Topic outline

Иностранный язык в профессиональной деятельности

Дисциплина: Английский язык в профессиональной деятельности

Направление подготовки: 33.04.01 Промышленная фармация

Курс: 1, семестр 2

Кафедра: иностранных языков

Количество часов: 72/2 (практические занятия: 28 ч., СРС: 44 ч.)

Форма контроля: зачёт

Форма занятий: практические

Аннотация: Данный электронный курс предназначен для самостоятельной работы магистрантов в рамках изучения дисциплины " Английский язык в профессиональной деятельности " и может быть использован для отработки пропущенных занятий и долгов. Курс разработан на основе действующей рабочей программы по дисциплине, основан на аутентичных материалах профессиональной направленности и его содержание включает необходимые темы для формирования иноязычной профессиональной коммуникативной компетенции магистрантов, обучающихся по направлению подготовки 33.04.01 Промышленная фармация. Тематическое деление курса не повторяет, но дополняет содержание РП; дополнительные учебные материалы непосредственно коррелируют с изучаемыми темами.

Основные темы для изучения:- Quality assurance;

- Medical pharmacology;

- Drug discovery and development;

- Drug Delivery Systems;

- Innovations in Pharmaceutical Industry;

- Dosage forms and prescriptions.

🧪T1.1. Quality assurance

- View

- View

- View Receive a grade Receive a pass grade or complete all available attempts

- View Receive a grade Receive a pass grade or complete all available attempts

- View Receive a grade Receive a pass grade or complete all available attempts

- View Receive a grade Receive a pass grade or complete all available attempts

🧪T1.2 Medical pharmacology

- View

Study the keywords before proceeding to the text

- View

Read the text which explains what medical pharmacology is and what it studies.

- View Receive a grade Receive a pass grade

This test corresponds to the text "What is medical pharmacology?" Make sure you have read it before you start?

- View Receive a grade Receive a pass grade or complete all available attempts

Match the words with their definitions

- View Receive a grade Receive a pass grade or complete all available attempts

Please, read and fill in the gaps with the proper words

- View

Watch the video about one of the most common viral diseases

- View Receive a grade Receive a pass grade or complete all available attempts

Make sure you have watched the video before you start.

- View

Read the text to know what antiviral drugs are.

- View Receive a grade Receive a pass grade or complete all available attempts

This task corresponds to the Text 2. "Antiviral drugs". Make sure you've read it before you start.

🧪T1.3 Medical pharmacology

Clarification to Text 1.

- Read the text thoroughly and copy down all the unknown words in your dictionary.

- Take this task seriously - you will have the translation task.

- View

Read the text which explains what vaccines are and why they are of importance.

- View Receive a grade Receive a pass grade or complete all available attempts

This test corresponds to the text "What are vaccines?" Make sure you have read it before you start!

- View Receive a grade Receive a pass grade or complete all available attempts

Match each word with its definition.

Make sure you have read "What are vaccines?" before you start!

- View Receive a grade Receive a pass grade or complete all available attempts

- View Receive a grade Receive a pass grade or complete all available attempts

Translate the words and word combinations.

Make sure you have read "What are vaccines?" before you start!

- View

Watch the video

- View Receive a grade Receive a pass grade or complete all available attempts

Choose the word in the drop-down menu.

Make sure you have watched the video before you start.

- View Receive a grade Receive a pass grade or complete all available attempts

Choose the word and drag it in the corresponding gap

Make sure you have watched the video before you start.

- View Receive a grade Receive a pass grade or complete all available attempts

Listen to the audio file and fill in the gaps with the words you hear.

🧪T1.3/2 Drug discovery and development

Clarification to Text 1.

- Read the text thoroughly and copy down all the unknown words in your dictionary.

- Take this task seriously - you will have the translation task.

- View Receive a grade Receive a pass grade or complete all available attempts

- View Receive a grade Receive a pass grade or complete all available attempts

- Do this exercise to know more about some terms used in the text you've read;

- Please, take your notebooks and pens and make up a dictionary of the unknown words while doing the exercise

- View Receive a grade Receive a pass grade or complete all available attempts

- Find the words corresponding to the given definitions in the Text you have read

- View Receive a grade Receive a pass grade or complete all available attempts

- View Receive a grade Receive a pass grade or complete all available attempts

- View Receive a grade Receive a pass grade or complete all available attempts

- View Receive a grade Receive a pass grade or complete all available attempts

- View Receive a grade Receive a pass grade or complete all available attempts

- View Receive a grade Receive a pass grade or complete all available attempts

- View Receive a grade Receive a pass grade or complete all available attempts

🧪T2.1 Drug Delivery Systems

Clarification to Text 1. What are Drug Delivery Systems?

- Read the text thoroughly and copy down all the unknown words in your dictionary.

- Take this task seriously - you will have the translation task.

- View

- View Receive a grade Receive a pass grade or complete all available attempts

- View Receive a grade Receive a pass grade or complete all available attempts

- View Receive a grade Receive a pass grade or complete all available attempts

- View Receive a grade Receive a pass grade or complete all available attempts

- View

- View Receive a grade Receive a pass grade or complete all available attempts

- View Receive a grade Receive a pass grade or complete all available attempts

- View Receive a grade Receive a pass grade or complete all available attempts

- View Receive a grade Receive a pass grade or complete all available attempts

- View Receive a grade Receive a pass grade or complete all available attempts

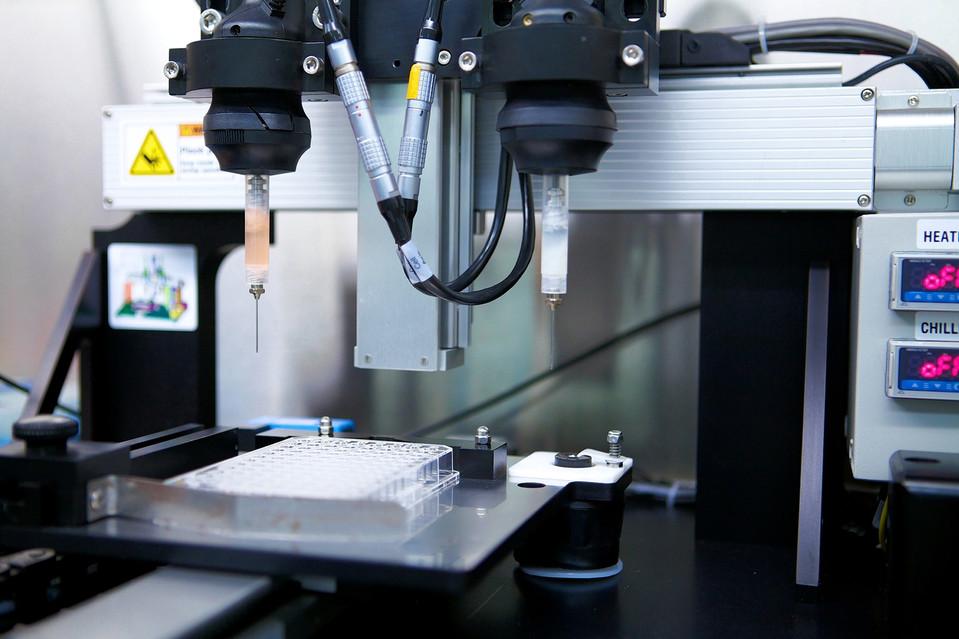

🧪T2.2 Innovations in Pharmaceutical Industry

3D printing drugs are the brand new technology in pharmacy which is driving the pharmaceutical industry towards personalized medicine.

Clarification to Text 1. 3D Printing in Pharmacy

- Read the text thoroughly and copy down all the unknown words in your dictionary.

- Take this task seriously - you will have the translation task.

- View

- View Receive a grade Receive a pass grade or complete all available attempts

- View Receive a grade Receive a pass grade or complete all available attempts

- View Receive a grade Receive a pass grade or complete all available attempts

- View Receive a grade Receive a pass grade or complete all available attempts

- View Receive a grade Receive a pass grade or complete all available attempts

- View

- View Receive a grade Receive a pass grade or complete all available attempts

- View

- View Receive a grade Receive a pass grade or complete all available attempts

- View Receive a grade Receive a pass grade or complete all available attempts

- View Receive a grade Receive a pass grade or complete all available attempts

- The video extracts are inside this test

- View Complete and pass the activity Receive a grade

🧪T2.3 Dosage forms and prescriptions

- View

- Study the table

- View Receive a grade Receive a pass grade or complete all available attempts

- View Receive a grade Receive a pass grade or complete all available attempts

- View

- View Receive a grade Receive a pass grade or complete all available attempts

- View Receive a grade Receive a pass grade or complete all available attempts

- View Receive a grade Receive a pass grade or complete all available attempts

- Read the example and try to read some prescriptions

Итоговое тестирование